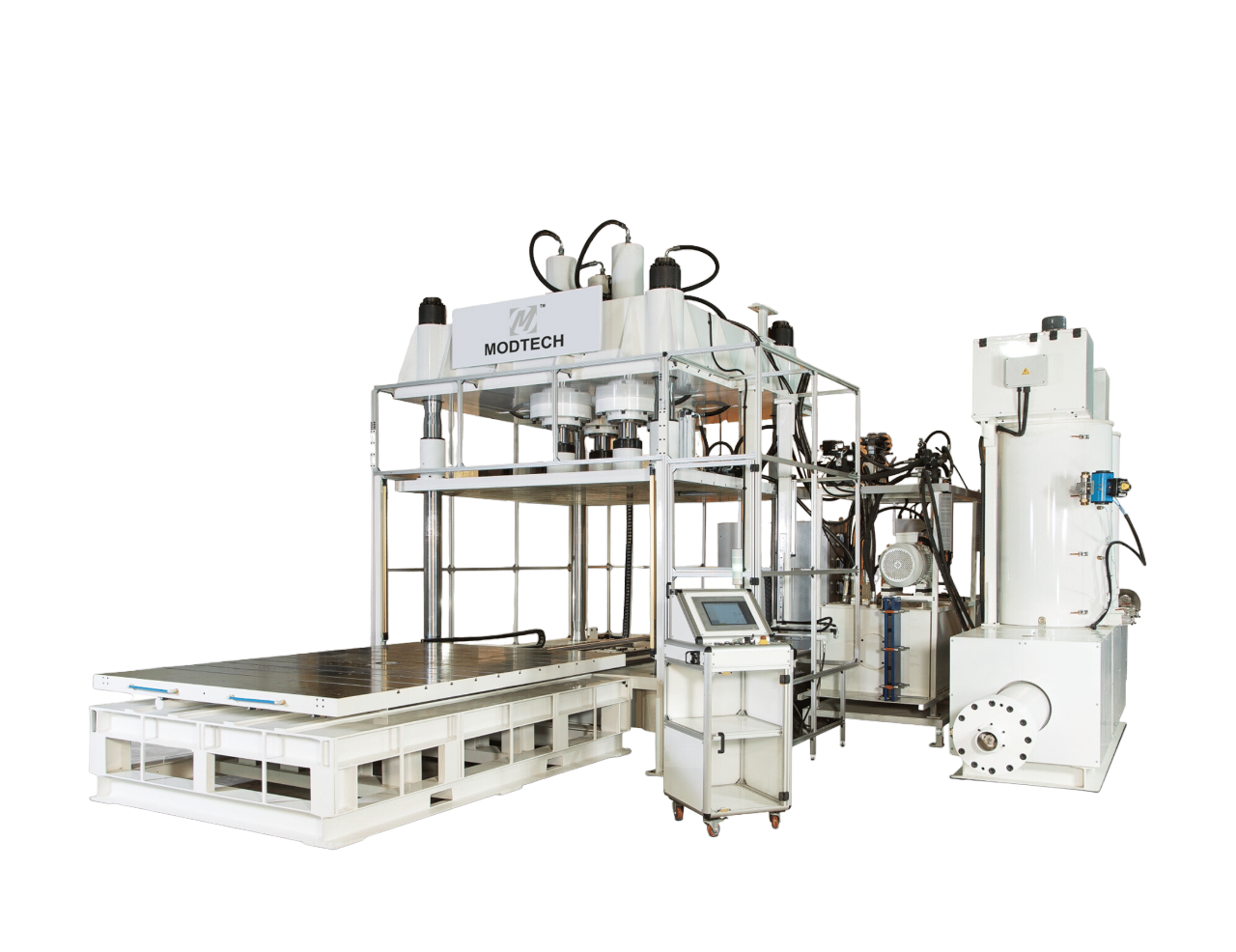

IGT Wax Injector

Exiting Features

- Easy access to load & operate larger IGT tooling

- Shuttle table positioned at an ergonomic working height

- Ample distance between platen tie rods

- Generous open daylight to accept cantilever type tooling

- Sophisticated Die Handling System: Shuttle table with T slots as per IS standards

- Multiple wax types capability

- Multiple nozzles capability

- Advanced wax re-circulation system from the nozzle tip and back to the wax tank

- Simple push button wax purge for wax consistency checkingsh-button wax purge for wax consistency checking

- Ultra high wax injection flow rate of up to 1000cc of conditioned wax per second

- Multiple clamping cylinder option for uniform die closing force

- Precise 5 stage wax injection system for wax pressure and flow

- Historical wax injection pressure and flow graphical mapping

- Single pointerg onomicmulti positional central control station

- Wide range of fully automatic functions & features

- Precise multiple zone PID wax temperature control

- Compact machine size designed for logical sectional installation

- Modular digital servo hydraulics

- Modular hydraulic power pack

- Light guard system in operator working area

- CE marked guards and electrical

- Clear observation panels in hazard areas with interlocking safety switches

- Operator definable pattern ejector

- Large wax injection shot size of up to 32 liters in a single injection

- Large Wax conditioning tank sizes of up to 200 liters capacity per wax tank

Clamping Unit

- New improved shuttle table design

- Larger clamping platens 2000mm x 2000mm

- Adjustable platen velocity

Control Unit

- Moveable control console with large HMI touch screen

- Remote machine access capability

- Operator accessible die recipe system

- Highly precise wax pressure & flow control system

- Highly precise control over clamping force and speeds

- Visual wax level indication

- Auto fault recognition system

- CE marked

Advanced Control System

- Large touch screen with icon based operating system

- Modtech M-ppek enabled (for supply with the machine or fitment at a later date if required)

- LAN enabled with inbuilt modem for remote access by Modtech technicians

- Advanced adaptable die recipe system

- Multi password access for machine operator-machine setter-maintenance personnel

- Automatic control diagnostic system for machine operation and electrical/ hydraulic systems

- Visual Wax Tank Level Indication on the Machine Touch Screen

- Instant machine error alarm functions

- Visual touch screen indication of machine PLC input-output status

- Visual interactive touch screen layout of wax injection path throughout the entire machine

- Visual touch screen indication of wax temperatures

- Touch screen facility for the operator to define machine auto cycle settings

- Touch screen accessible machine cycle records

- USB die recipe back up

Selectable Machine Operator

- 3 axis nozzle positioning

- Platen cooling

- Paste wax injection capability

- PADS (Platen Anti Deflection System)

- PLCS (Platen Laser Centering System)

- ALS (Auto Lubrication System)

- Multiple nozzle configurations

- Multiple wax tanks

- Multiple clamp cylinders