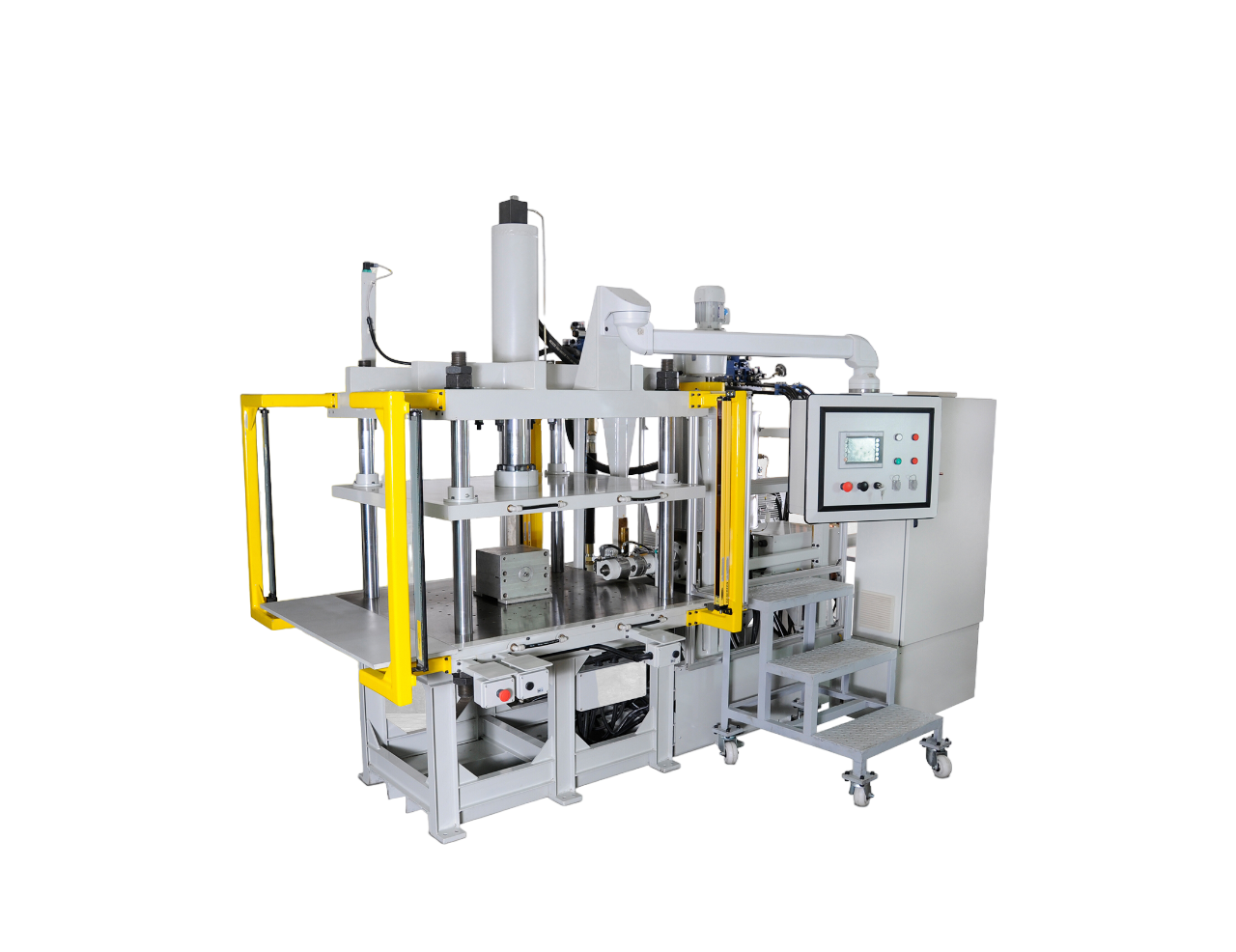

4-Pillar Ceramic Injector

Modtech produced its first-ever Ceramic injection machine back in 2008 and the design was 4 Pillar type. Since then, our customers have widely accepted our 4 Pillar type of machine for their reliable production and our machines have also proven the same by providing expected results.

Salient Features

- Full recirculation of ceramic material from tank to nozzle tips

- Specific purpose injection System

- Machine built for continual and long-life operation

- Quick seal replacement

- Tank and injection system move together

- Push button ceramic purge facility

- Heavy duty tank and agitator

- Hardened parts

- Unique heat zone design to minimize heat loss

- Modular digital servo hydraulics

- CE marked guards and electrical

- Multiple die mounting options

- Platen cooling channels

- Optional PLCS platen laser centering system

Specific Features

- Platens are turned 90° to enable injection of lengthways cantilever tooling often used for ceramic core production

- Optional Injection Type: Conventional piston-based injection or screw & barrel type injection

- Optional Nozzle Tip Closure: Spring checked valve or cylinder driven pin

Control Systems

- Large touch screen with easy program upload facility

- M-ppek enabled

- Inbuilt modem

- USB connection

- Icon-based control with operator-friendly interaction

- LAN enabled with Remote Machine Access

- 200 die recipe system

- Multi-user password access

- Diagnostics for Electricals /Auto Cycle

- Historical and Dynamic Graphing

- Ceramic level control & indication

- Alarm systems protection